Introduction

Advanced materials and manufacturing techniques are transforming modern industries by enabling the production of stronger, lighter, and more efficient products. These innovations are driven by breakthroughs in materials science, nanotechnology, and automation. The combination of advanced composites, smart materials, and high-precision manufacturing methods such as additive manufacturing (3D printing) is revolutionizing fields like defense, aerospace, automotive, and healthcare.

Key Advanced Materials and Their Properties

- Nanomaterials: Materials engineered at the nanoscale, such as graphene and carbon nanotubes, provide exceptional strength, electrical conductivity, and thermal resistance. These are used in flexible electronics, energy storage, and ultra-strong lightweight armor.

- High-Strength Alloys: Advanced metal alloys, such as titanium-aluminum alloys and shape-memory alloys, offer high durability, corrosion resistance, and adaptability for applications in aerospace, biomedical implants, and structural engineering.

- Smart Materials: These materials can change properties in response to environmental stimuli. Examples include self-healing polymers, shape-memory materials, and piezoelectric materials used in sensors and adaptive structures.

- Advanced Composites: Fiber-reinforced composites, such as carbon fiber-reinforced polymers (CFRP) and ceramic matrix composites (CMC), provide high strength-to-weight ratios, making them ideal for aircraft, military vehicles, and space exploration.

Manufacturing Innovations and Techniques

- Additive Manufacturing (3D Printing): 3D printing allows for rapid prototyping, custom part manufacturing, and reduced material waste. Industries such as healthcare, automotive, and defense use this technology to produce intricate and lightweight components efficiently.

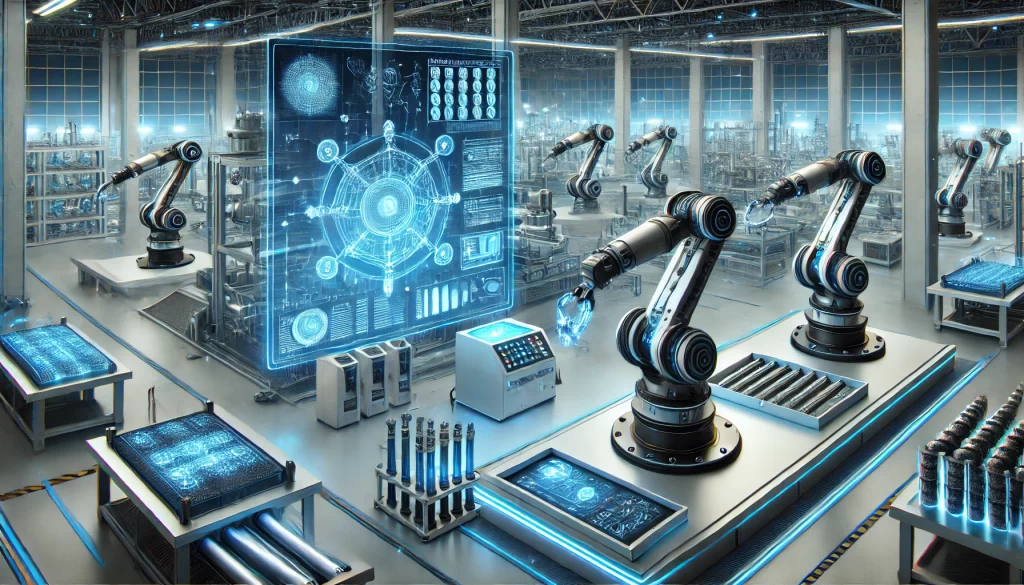

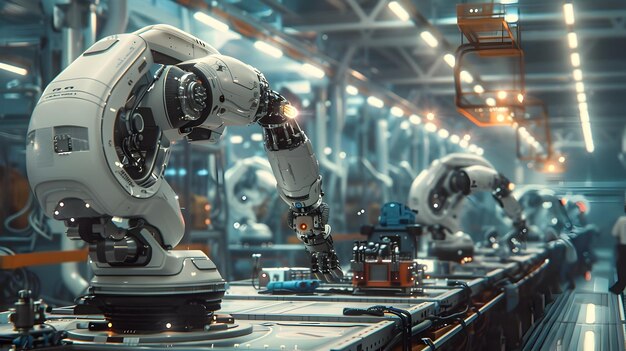

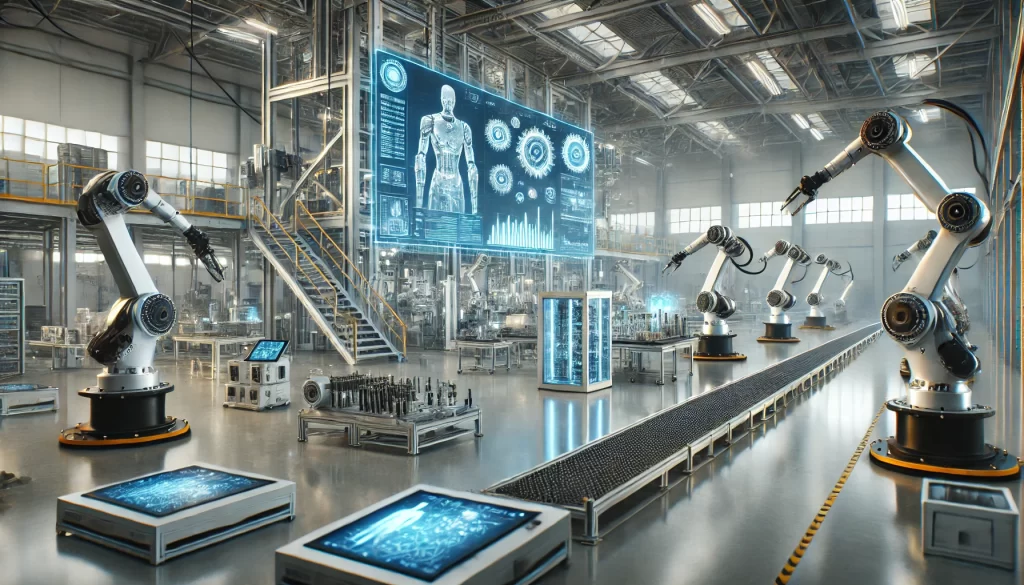

- Advanced Robotics and Automation: Smart factories equipped with AI-driven robotic systems improve precision, reduce human error, and optimize manufacturing efficiency in large-scale production.

- Sustainable Manufacturing: Eco-friendly production methods, including biodegradable materials, recycling technologies, and energy-efficient processes, are reducing the environmental impact of industrial production.

- 4D Printing: This emerging technology enables materials to change shape or function over time based on environmental triggers, leading to innovations in medical implants, aerospace components, and self-assembling structures.

Applications Across Industries

- Defense and Security: Lightweight armor, stealth materials, and self-healing coatings enhance military equipment and personnel protection.

- Aerospace and Automotive: High-performance composites and 3D-printed components reduce weight, improve fuel efficiency, and enhance safety in aircraft and vehicles.

- Medical and Biotechnology: Biocompatible materials, 3D-printed prosthetics, and smart drug-delivery systems are advancing healthcare technologies.

- Energy and Electronics: Nanomaterials in batteries, flexible solar panels, and heat-resistant coatings improve energy storage and efficiency.

Future of Advanced Materials and Manufacturing

The future of this field lies in the development of ultra-lightweight and durable materials, AI-driven design optimization, and fully autonomous smart factories. Researchers are exploring meta-materials (engineered materials with unique properties) and self-replicating manufacturing systems to push the boundaries of what’s possible. As these technologies evolve, industries will benefit from more sustainable, efficient, and high-performance solutions, shaping the next generation of engineering and production.

Conclusion

Advanced materials and manufacturing technologies are driving a new era of innovation across multiple industries. By combining cutting-edge materials like nanocomposites, high-strength alloys, and smart polymers with advanced manufacturing techniques such as 3D printing and AI-driven automation, industries can achieve unprecedented levels of efficiency, durability, and sustainability. These advancements are not only improving product performance but also reducing costs, enhancing safety, and minimizing environmental impact.

As research continues, the future of advanced materials and manufacturing will see the integration of self-healing materials, quantum-based manufacturing, and even bioengineered substances that can adapt to their surroundings. The development of lighter, stronger, and more intelligent materials will revolutionize everything from aerospace and defense to healthcare and renewable energy. Embracing these innovations will be essential for industries looking to stay competitive in an increasingly technology-driven world.