Introduction

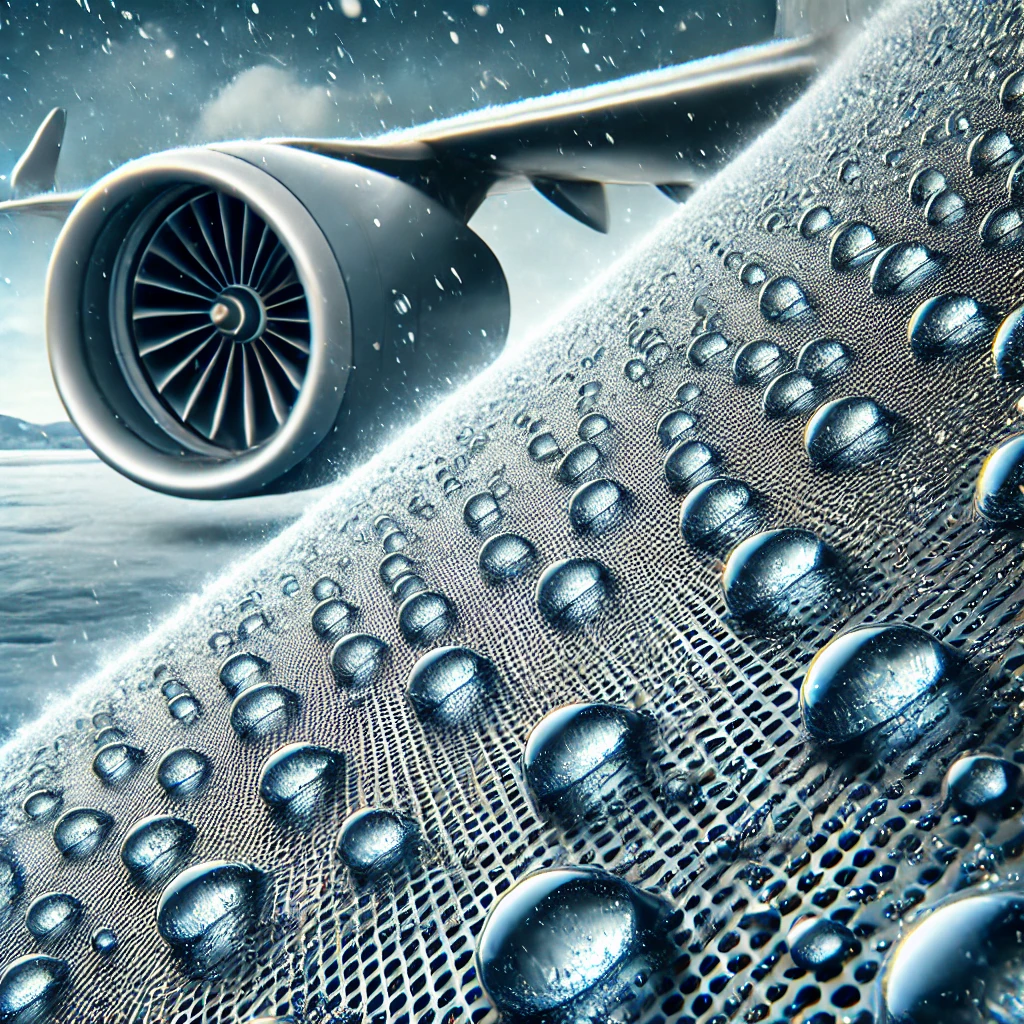

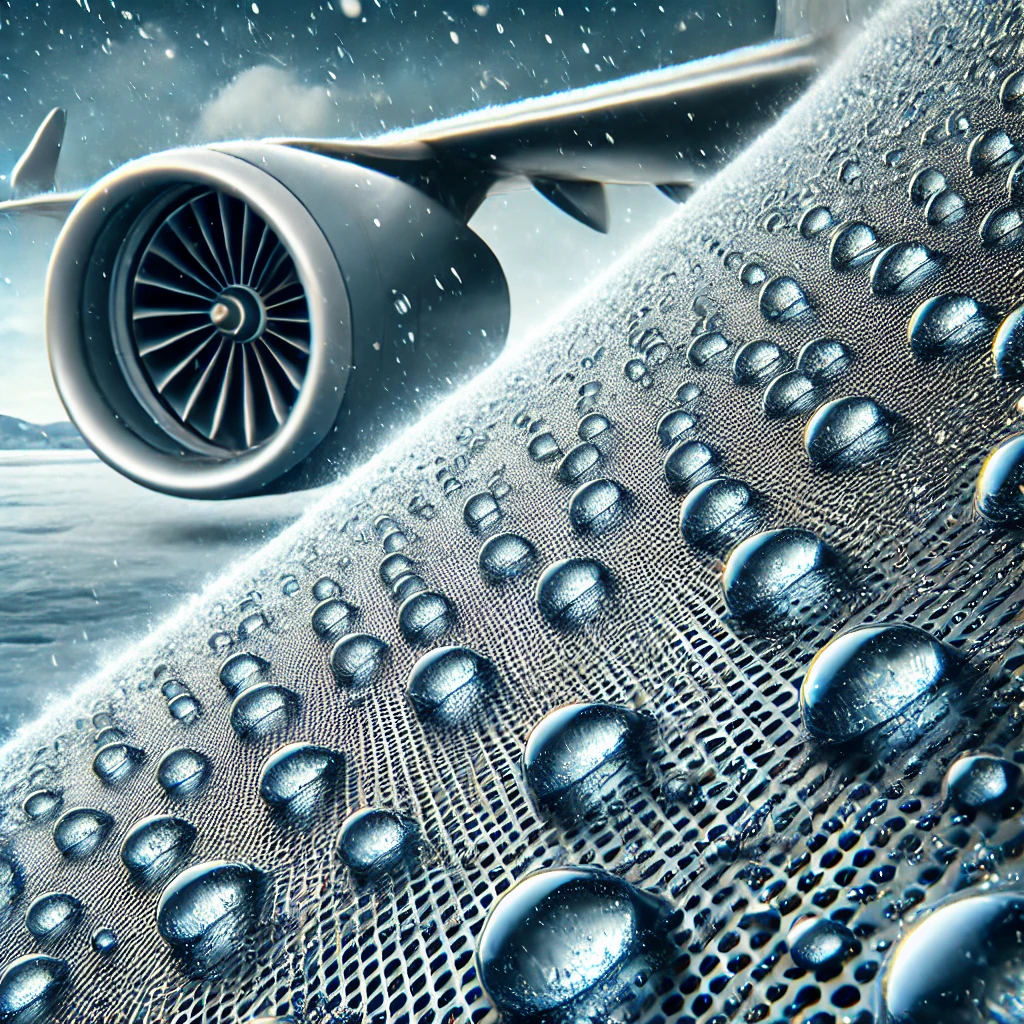

Anti-icing nanocoatings have emerged as an innovative solution to prevent ice accumulation on surfaces in extreme cold conditions. These coatings utilize nanotechnology to create surfaces that repel water and inhibit ice formation. Their application spans various industries, including aerospace, automotive, energy, and infrastructure, offering an effective way to enhance safety and efficiency.

How They Work

Anti-icing nanocoatings function by employing hydrophobic (water-repellent) or icephobic (ice-repelling) properties at the nanoscale. These coatings are designed to minimize ice adhesion by reducing the surface energy, preventing water droplets from freezing and forming ice layers. Some nanocoatings use superhydrophobic materials, while others incorporate phase-change materials that delay ice nucleation.

Uses of Anti-Icing Nanocoating

- Aerospace Industry: Prevents ice formation on aircraft wings and rotor blades, enhancing flight safety.

- Automotive Industry: Used on windshields and mirrors to reduce ice buildup, improving visibility.

- Energy Sector: Protects wind turbine blades and power lines from ice accumulation, ensuring consistent energy production.

- Infrastructure: Applied to roads, bridges, and railway tracks to minimize ice hazards and improve public safety.

- Marine Applications: Prevents ice buildup on ship hulls and offshore structures, reducing maintenance costs.

Advantages

- Enhanced Safety: Reduces ice accumulation, preventing accidents in transportation and infrastructure.

- Energy Efficiency: Lowers energy consumption in de-icing processes, particularly in aviation and power grids.

- Long-Lasting Protection: Provides durable ice resistance with minimal maintenance requirements.

- Environmental Benefits: Reduces reliance on chemical de-icers, minimizing ecological impact.

Disadvantages

- Cost: High initial investment compared to traditional de-icing methods.

- Durability Concerns: Some coatings may wear off over time due to harsh environmental conditions.

- Application Challenges: Requires precise application techniques for optimal performance.

- Limited Effectiveness in Extreme Conditions: Some coatings may struggle in extreme freezing environments.

Future Scope

The future of anti-icing nanocoatings looks promising with ongoing research aimed at improving durability, efficiency, and affordability. Scientists are exploring self-healing coatings, advanced nanomaterials, and environmentally sustainable formulations. As industries continue to seek effective de-icing solutions, nanocoatings are expected to play a critical role in enhancing safety and performance across various sectors.

Anti-icing nanocoatings represent a significant technological advancement, addressing ice-related challenges in multiple industries. With continuous innovation, they have the potential to revolutionize ice management, offering sustainable and efficient solutions for the future.